|

ANPING COUNTY JINHAO WIRE MESH CO., LTD.

|

expanded

| Price: | 2.3~3.2 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

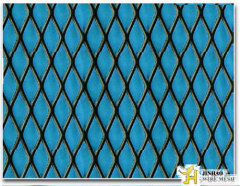

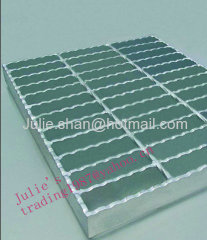

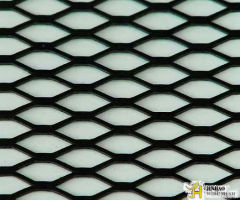

Expanded metal sheet, expanded sheet, aluminum expanded metal, stainless expanded metal, diamond shape mesh, stretched metal, xpm expanded metal,

Product Description Key related words:

Expanded metal sheet, expanded sheet, aluminum expanded metal, stainless expanded metal, diamond shape mesh, stretched metal, xpm expanded metal, flattened metal, gothic mesh, expanded metal grating, expanded metal mess, walk way.

Introduction:

A major advantage of expanded metal sheet is that the mesh is formed from a single piece of material so the process is not wasteful and therefore cost effective. The material is cut and stretched while still leaving it attached at the knuckle. This allows it to retain its shape when cut and cannot separate or fray. Often cutting to shape is the only fabrication needed. It has excellent corrosion resistance when suitably coated, and the uncut knuckles support weight and withstand stress better than jointed welds or woven materials.

Expanded metal sheet can be supplied in a variety of finishes, thickness, raised or flattened. Flattened is smoother and does not indent soft materials if this is a consideration but is not as strong as the more robust raised mesh. Powder coating in your choice of colour will enhance its aesthetic appearance and add to its corrosion resistance as would plastic coating.

Technical terms:

SWD: 2.5mm-50mm (Short Way of the Diamond), the distance from the middle of the bond on one side to the middle of the bond on the opposite side.

LWD: 3mm-100mm(Long Way of the Diamond) is the distance across the largest dimension of the diamond measured halfway between the diamonds.

Width: 0.5m-2.7m, Length: 1m-3.6m

Thickness(gauge): Up to 8mm, Original thickness of metal before expanding.

Strand Width: 0.3mm to 8mm, Amount of metal between diamonds to produce one strand.

SWD, LWD Direction: Parallel to Length or Parallel to Width

Pattern of opening:

Diamond, Square, gothic, Hexagonal and Round patterns. Collection and Stil-Tech lines

Sheet materials:

Steel cold-rolled, hot dipped zinc plated, galvanized, carbon steel sheets can be electro galvanized or, zinc plated, stainless steel, aluminium, copper, brass, plastics

Shearing types:

Bond shearing, random shearing

Applications:

Filters, Reinforcing, Security Guarding, Exhibition Stands, Machinery Guards, Fan Guards, Racking, Security Cages, Grilles, Compounds, Tree Guards Window Guards, Stairways, Fire Guards, Enclosures, Litter Bins, Ventilator Guards, Catwalks, Partitions, Fencing, Filter Support Tubes, Lockers, Cages & Pens.

Expanded metal sheet, expanded sheet, aluminum expanded metal, stainless expanded metal, diamond shape mesh, stretched metal, xpm expanded metal, flattened metal, gothic mesh, expanded metal grating, expanded metal mess, walk way.

Introduction:

A major advantage of expanded metal sheet is that the mesh is formed from a single piece of material so the process is not wasteful and therefore cost effective. The material is cut and stretched while still leaving it attached at the knuckle. This allows it to retain its shape when cut and cannot separate or fray. Often cutting to shape is the only fabrication needed. It has excellent corrosion resistance when suitably coated, and the uncut knuckles support weight and withstand stress better than jointed welds or woven materials.

Expanded metal sheet can be supplied in a variety of finishes, thickness, raised or flattened. Flattened is smoother and does not indent soft materials if this is a consideration but is not as strong as the more robust raised mesh. Powder coating in your choice of colour will enhance its aesthetic appearance and add to its corrosion resistance as would plastic coating.

Technical terms:

SWD: 2.5mm-50mm (Short Way of the Diamond), the distance from the middle of the bond on one side to the middle of the bond on the opposite side.

LWD: 3mm-100mm(Long Way of the Diamond) is the distance across the largest dimension of the diamond measured halfway between the diamonds.

Width: 0.5m-2.7m, Length: 1m-3.6m

Thickness(gauge): Up to 8mm, Original thickness of metal before expanding.

Strand Width: 0.3mm to 8mm, Amount of metal between diamonds to produce one strand.

SWD, LWD Direction: Parallel to Length or Parallel to Width

Pattern of opening:

Diamond, Square, gothic, Hexagonal and Round patterns. Collection and Stil-Tech lines

Sheet materials:

Steel cold-rolled, hot dipped zinc plated, galvanized, carbon steel sheets can be electro galvanized or, zinc plated, stainless steel, aluminium, copper, brass, plastics

Shearing types:

Bond shearing, random shearing

Applications:

Filters, Reinforcing, Security Guarding, Exhibition Stands, Machinery Guards, Fan Guards, Racking, Security Cages, Grilles, Compounds, Tree Guards Window Guards, Stairways, Fire Guards, Enclosures, Litter Bins, Ventilator Guards, Catwalks, Partitions, Fencing, Filter Support Tubes, Lockers, Cages & Pens.

| Item Number | LWD(mm) | SWD (mm) | Strand Width (mm) | Strand Gauge (mm) | % Free Area | Approx. Kg/M2 |

|---|---|---|---|---|---|---|

| 1 | 6.05 | 3.38 | 0.8 | 0.5 | 50 | 2.1 |

| 2 | 10.24 | 5.84 | 0.8 | 0.5 | 75 | 1.2 |

| 3 | 10.24 | 5.84 | 1.2 | 0.9 | 65 | 3.2 |

| 4 | 14.27 | 5.84 | 1.2 | 0.9 | 60 | 3.2 |

| 5 | 19.05 | 7.42 | 1.2 | 0.9 | 60 | 3.4 |

| 6 | 5.80 | 3.50 | 0.8 | 0.6 | 44 | 2.1 |

| 7 | 19.00 | 7.40 | 1.7 | 1.0 | 55 | 3.4 |

| 8 | 30.50 | 11.70 | 2.4 | 1.6 | 62 | 4.9 |

| 9 | 30.50 | 11.70 | 2.4 | 1.2 | 61 | 3.8 |

| 10 | 38.00 | 16.50 | 2.2 | 1.6 | 76 | 3.4 |

| 11 | 50.80 | 22.50 | 2.5 | 2.5 | 77 | 4.4 |

| 12 | 50.80 | 22.50 | 3.0 | 1.6 | 80 | 3.4 |

| 13 | 50.80 | 22.50 | 3.9 | 3.0 | 69 | 8.1 |

| 14 | 50.80 | 22.50 | 3.1 | 3.0 | 71 | 6.5 |

| 15 | 76.20 | 33.90 | 3.5 | 3.0 | 78 | 4.9 |

| 16 | 85.70 | 40.60 | 3.2 | 3.0 | 84 | 3.7 |

| 17 | 101.60 | 50.80 | 5.0 | 3.0 | 82 | 4.7 |

| 18 | 101.60 | 50.80 | 3.4 | 3.0 | 85 | 3.1 |

| 19 | 114.30 | 39.30 | 4.6 | 3.0 | 82 | 5.4 |

| 20 | 200.0 | 75.0 | 6.3 | 3.0 | - | 3.6 |

| Item Number | L. W. M | S. W. M | Strand Width | Strand Gauge | % Free Area | Approx. Kg/M2 |

|---|---|---|---|---|---|---|

| 1 | 6.05 | 3.38 | 0.5 | 0.8 | 50 | 2.1 |

| 2 | 10.24 | 5.84 | 0.5 | 0.8 | 75 | 1.2 |

| 3 | 10.24 | 5.84 | 0.9 | 1.2 | 65 | 3.2 |

| 5 | 3.80 | 2.10 | 0.8 | 0.6 | 46 | 2.1 |

| 6 | 14.20 | 4.80 | 1.8 | . 9 | 52 | 3.3 |

| 7 | 24.40 | 7.10 | 2.4 | 1.1 | 57 | 3.4 |

| 8 | 23.10 | 5.80 | 3.2 | 1.5 | 43 | 6.3 |

| 9 | 32.70 | 10.90 | 3.2 | 1.5 | 59 | 4.3 |

| 10 | 33.50 | 12.40 | 2.3 | 1.1 | 71 | 2.5 |

| 11 | 42.90 | 14.20 | 4.6 | 2.7 | 58 | 8.6 |

| 12 | 39.10 | 18.30 | 4.7 | 2.7 | 60 | 7.6 |

| 13 | 43.20 | 17.80 | 3.2 | 1.5 | 69 | 3.2 |

| 14 | 69.80 | 37.10 | 5.5 | 2.1 | 75 | 3.9 |

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!